| Size | 15 mm (1/2”) to 150 mm (6”). |

|---|---|

| Body | Cast Iron : IS 210 Gr. FG 200 SG Iron- ASTM A536, Gr.60-40-18 (DIN 0.7043)(GGG40.3). Cast Steel: ASTM A 216 Gr. WCB St.St.: ASTM A 351CF8(SS304),or ASTM A351CF8M(SS316). |

| Pressure Temp. rating | As per ANSI B 16.5 Class 150. |

| End Connection | Flanged as per ANSI B 16.5 Class 150. |

| Trim | St. St. AISI 304/316 Ground and Burnished. |

| Stem Packing | Self adjusting, Spring loaded Teflon packing |

| Plug and Seat | St. St.: AISI 420/304/316 |

| Seating | Soft seated PTFE. Optional-Viton/EPDM, Buna Nitrile. |

| Leakage | Soft Seated Class VI , as per ANSI B 16.104-1976. |

| Characteristic | On-Off, normally close/open. |

| Working Fluid Press | Refer to table below |

| Working Temperature | On steam-continuous 155°C, Intermittent 180°C, EPDM 135°C, VITON 180°C. |

| Cylinder, Cover, Body & Piston: | Glass filled polyamide. |

| Actuator Working Pressure | 3.5 to 6 bar (refer to graph) |

| Piston Packing | Buna Nitrile. |

| Actuator Spring | IS 4454 Grade III, duly painted |

| Operating cycles | Upto 50 mm 300 cy/hr.,(tested on air,on other fluids this figure may vary). For other size details, refer to AVCON. |

| Life Expectancy | Over one million cycles (lab tested in ideal condition) |

| Air Quality | Lubricated filtered and free of moisture. Shop air or dry instrument quality air. |

| Max. Operating | Refer to graph |

| Accessory | Air lock, position indicating limit switch box, solenoid valve, filter regulator gauge. Other accessories available on application |

| Application | For control of air, water, oil, gas, steam in textile, power generation, paper & pulp, chemical, petrochemical industries, PSA nitrogen system, air dryer, gas generator and others. |

| Back Pressure | Suitable upto 2.5 bar. |

| Instruction Manual: | Refer to IM 5812M/5822M |

Technical Data

5812M-5822M.pdf

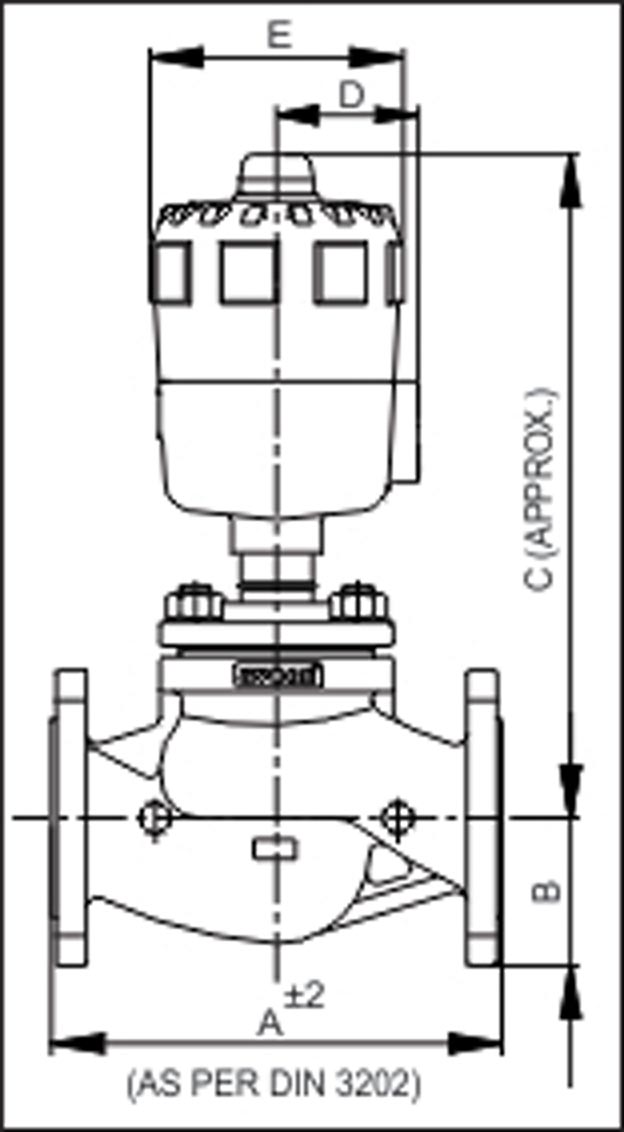

Diagrams

CATEGORIES

Solenoid Valve

R Star Series

- - View All

- - Internal Pilot Operated Valves

- - Direct Acting type

- - 3-way Manifold Mounted Valves

- - Interrnal Pilot Operated & External Pilot Operated

- - Universal Ported

- - Force Lift Type

- - Poppet Type

- - Midget Type Direct Acting

- - Namur Mounting / Namur Based Valves

- - Poppet Type, Universal Ported

- - Pilot Operated, Diagram Valve

- - Pilot Operated, Spool Type

Gas Products

Ball Valves

Butterfly Valves

Pneumatic On/Off Valves

Pharma & Diaphragm Seated Valves

Control Valves

Actuators

Angle Seated Valve

Switch Boxes